Quick summary: BSPP (British Standard Pipe Parallel), also called G-thread, is the international standard for parallel pipe threads used across Europe, Asia and many Commonwealth countries. Unlike tapered pipe threads, BSPP has a constant diameter along its length and depends on an external sealing element (O-ring, bonded washer, gasket) to make a pressure-tight joint. This guide explains the history, standards, dimensions, sealing practices, installation guidance, failure modes, and practical decision-making for hydraulic and industrial use — with application-focused tips you can use when specifying HGW Hydraulics BSPP fittings.

Key standards and definitions referenced in this article: ISO 228-1 (parallel pipe threads), BS/EN references for pipe threads and port face standards, and widely used manufacturer guidance for sealing and installation.

What is BSPP (G) thread?

BSPP stands for British Standard Pipe Parallel. It is a parallel (straight) pipe thread form standardized under ISO 228-1 and traditionally derived from the Whitworth thread family that uses a 55° thread flank angle and rounded crests and roots. BSPP is commonly marked with a leading “G” (for example, G1/4, G1/2) and is designed so the male and female threads mate without producing an interference seal — sealing is achieved with a face seal (O-ring, gasket, bonded washer) or other sealing element placed between the two mating faces.

Why BSPP exists — engineering tradeoffs & history

The BSPP form is not an arbitrary tradition. It evolved from Joseph Whitworth’s 19th-century standardization work and later pipe-thread standards that prioritized interchangeability, manufacturability, and reusability. Designers selected a parallel thread form to allow repeated assembly/disassembly (less risk of galling and over-tightening compared with tapered threads) and to permit a controlled, replaceable static sealing surface (face seal) for pressure containment. Whitworth’s original rounded 55° profile proved robust for industrial use and influenced subsequent BSP standards.

BSPP vs BSPT vs NPT — what’s the difference?

It’s essential to understand how BSPP differs from other common pipe threads:

- BSPP (G, parallel): 55° flank angle; constant diameter; seals with O-ring/gasket/washer or face seal; defined by ISO 228-1.

- BSPT (R, tapered): 55° flank angle; tapered male or female; sealing often achieved by wedge action of threads (mechanical) plus thread sealant.

- NPT (tapered, U.S. standard): 60° flank angle and Sellers thread form; seals by thread compression and sealant; not interchangeable with BSP family due to angle and pitch differences.

Because of differences in pitch and flank geometry, mixing BSP (any type) with NPT is a common source of leakage or mechanical damage — do not assume interchangeability.

BSPP dimensions (common G sizes)

The BSPP system uses nominal pipe sizes (inches) as labels rather than the actual measured thread OD. The table below lists commonly used sizes and the typical external diameters, pitches and TPI — useful for procurement and inspection. (Values are derived from ISO 228-1 / standard thread charts — always verify with manufacturer datasheets for critical fits.)

| Nominal size | Approx OD (mm) | Pitch (mm) | TPI |

|---|---|---|---|

| G1/8 | 9.73 | 0.907 | 28 |

| G1/4 | 13.16 | 1.337 | 19 |

| G3/8 | 16.66 | 1.337 | 19 |

| G1/2 | 20.99 | 1.814 | 14 |

| G3/4 | 26.44 | 2.309 | 11 |

| G1 | 33.25 | 2.309 | 11 |

| G1¼ | 41.91 | 2.967 | 11 |

| G1½ | 47.80 | 3.969 | 11 |

| G2 | 59.61 | 4.877 | 11 |

Notes: pitch/TPI and OD tolerances are standardized (typical internal/external tolerance classes 6H/6g for many BSPP fits). For precision or custom parts, rely on HGW Hydraulics datasheets and ISO 228-1 references.

How BSPP seals — O-rings, bonded seals and best practices

Because BSPP threads are parallel, pressure-tightness is achieved through a sealing element placed on the face or in a groove rather than by the thread interference. Common sealing methods include:

- Face O-ring (port O-ring): a common hydraulic pattern where the male end has a flat sealing face and an O-ring groove; the O-ring compresses against the female port face to form the seal. Widely used in hydraulic fittings and instrumentation.

- Bonded (captive) washer: a metal washer with a vulcanized elastomer sealing lip — popular where easy assembly and reliable re-sealing are required.

- Flat gasket / copper washer: used for lower pressure or where material compatibility dictates a metal-to-metal supported soft seal.

- Thread sealant (PTFE tape or anaerobic paste): sometimes used in combination with BSPP when a thread-only seal is attempted (not recommended as primary seal for face-sealed BSPP installations).

For material selection of O-rings (NBR, EPDM, FKM, HNBR etc.), review fluid compatibility, temperature, and expected pressure/pressure cycles. The Parker O-Ring Handbook is a canonical source for groove design, material properties and recommended compression ratios; use it as a design reference when specifying BSPP face seals.

O-ring groove design & installation details

Effective face sealing depends on correct groove geometry and controlled O-ring compression. Key points:

- Groove depth and width must be sized for intended O-ring cross-section and expected compression (often 10–30% compression depending on dynamic/static use).

- Finish of sealing faces should be smooth and free from burrs; sharp corners or debris can cut or extrude the O-ring under pressure.

- During assembly, lightly lubricate O-rings to avoid pinching and to achieve predictable torque readings.

Proper groove design references and material guidance are available from seal manufacturers and the Parker handbook. If a BSPP fitting will be used in cyclic or high-pressure duty, consider smaller compression or harder elastomer compounds to reduce extrusion risk.

Installation: torque table & step-by-step checklist

Installation torque depends on size, material, whether the connection is lubricated, and whether an O-ring or bonded washer is fitted. Manufacturer port assembly guides (e.g., Parker port assembly literature) provide torque guidance and stepwise procedures. General practical checklist:

- Inspect threads and sealing surfaces; remove burrs and debris.

- Fit the O-ring or bonded washer into the correct groove; lightly lubricate the seal.

- Hand-tighten the fitting to ensure correct seating.

- Use calibrated torque wrench and apply the recommended torque for the size and material.

- Perform pressure test or leak test (pressure-hold / bubble test / instrumentation) before putting system into service.

For port fittings and hydraulic components, follow manufacturer torque tables and two-wrench techniques to avoid imparting twist loads on the assembly. Detailed port assembly instructions can be found in distributor and OEM literature.

Common failure modes & field troubleshooting

Understanding failure modes reduces downtime. Common BSPP-related failures include:

- Seal extrusion or lip failure: caused by insufficient groove support, inappropriate O-ring hardness, or excessive pressure spikes.

- Cut or nicked O-ring: often occurs during assembly because of sharp edges or debris.

- Galling or thread seizure: from dissimilar metals, lack of lubrication, or over-torque — particularly in stainless steel fittings.

- Corrosion or plating failure: leading to rough sealing surfaces or trapped contaminants that abrade seals.

Troubleshooting procedure: identify leakage location (face vs thread), inspect seal and groove, check torque history, and sample materials for compatibility. Where possible, replace seals and re-test before replacing metalwork. Failure photo libraries and root-cause analyses are extremely helpful to maintenance teams. (See O-ring handbook and manufacturer case studies for in-depth guidance.)

Pressure ratings & material guidance

Pressure capability is a function of component geometry, material, and sealing method. In practice:

- Brass and bronze BSPP fittings perform well for low-to-medium pressures (plumbing, instrumentation).

- Carbon steel and stainless steel BSPP fittings are used for higher-pressure hydraulic systems; properly designed face seals (O-ring in gland or bonded washer) can reliably seal in high-pressure services (consult supplier for specific pressure ratings — e.g., hydraulic couplings and fittings will list safe working pressures by size and material).

When specifying parts for critical high-pressure service, always request manufacturer pressure charts and test certificates; do not assume that a thread type alone guarantees safe performance. HGW Hydraulics provides datasheets and pressure ratings for its BSPP fittings — request size-specific ratings for high-pressure applications.

Compatibility, adapters and practical procurement advice

Key procurement tips:

- Do not mix BSPP with NPT directly — pitch and flank differences make them incompatible for pressure-tight joints. Use dedicated adapters engineered to convert between standards where necessary.

- Always specify whether a BSP thread is face-sealing (O-ring) or non-sealing (mechanical) when ordering ports and fittings.

- Measure actual OD and pitch when replacing legacy parts — nominal size names can be misleading.

- Ask suppliers for 2D/3D CAD models and sample parts to validate fit before production purchases. HGW Hydraulics can supply CAD models and custom BSPP adaptors on request.

When to choose BSPP — use cases & selection flow

_1757666072_WNo_1600d900.webp)

Choose BSPP when your system requirements include:

- Frequent assembly/disassembly or maintenance (parallel threads reduce risk of galling from repeated tightening).

- Need for a reliable face seal (O-ring or bonded washer) with predictable re-seal performance.

- Geographies or supply chains where BSP is the regional norm (Europe, Asia, Australia, many Commonwealth countries).

Consider BSPT or ORFS/metric flange patterns for male-thread-sealing or high-cycle/high-pressure environments where metal-to-metal or bonded seals are preferred.

Case study (illustrative)

Example: A mid-sized hydraulic OEM migrated local instrument ports from an improvised tapered thread assembly (frequent micro-leaks and rework) to standardized BSPP ports with properly designed O-ring grooves and bonded washers. After rework and standardized torques, leak incidents reported during field commissioning dropped by over 80% and maintenance time for the affected assembly decreased significantly. The takeaway: standardized parallel ports plus correct sealing elements reduce service costs and increase uptime.

HGW Hydraulics — BSPP fittings & customization

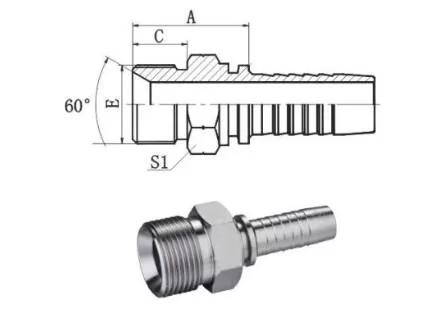

As a manufacturer and supplier of hydraulic fittings, HGW Hydraulics offers a range of BSPP (G) threaded fittings and port adaptors in brass, carbon steel and stainless steel. Typical product offerings you may request:

- Male BSPP to hose tail adaptors (G1/4, G3/8, G1/2, etc.) with O-ring seat.

- BSPP port elbows and flat-face connectors with bonded seals.

- Custom BSPP adaptors (BSPP→NPT, BSPP→Metric) with certified pressure ratings and CAD models on request.

When asking HGW for a quote, include: nominal thread size, material, required sealing method (O-ring/bonded washer), and application pressure/temperature. This allows HGW to recommend the correct compound, plating, and proof-testing level for your application.

FAQ

Can BSPP and BSPT be used together?

Not directly for pressure-tight joints. BSPP is parallel and requires a face seal; BSPT is tapered and seals by thread wedge. In practice, a BSPP female port can accept a BSPT male thread if the port is designed for it, but this is an application-dependent arrangement and usually requires a dedicated sealing approach and careful design. Always follow supplier guidance.

Is BSPP the same as G thread?

Yes. The “G” designation (e.g., G1/4) commonly refers to ISO parallel pipe threads standardized under ISO 228-1 — commonly called BSPP in industry parlance.

How do I measure a BSPP thread?

Measure the external thread OD with calipers at the first complete crest and verify the thread pitch using a thread gauge or by counting threads per inch. Confirm nominal size by cross-checking OD with a thread chart. For critical assemblies, measure pitch, OD and profile and compare to supplier drawings.

What O-ring material should I choose?

Base the choice on fluid compatibility and temperature. NBR (Nitrile) is common for mineral oils; FKM (Viton) for hot hydraulic fluids and aggressive chemicals; EPDM for hot water/steam; HNBR for improved heat and dynamic performance. Consult O-ring manufacturer compatibility charts (or the Parker O-Ring handbook) for exact guidance.

Want HGW to help spec or quote BSPP fittings for your project? Provide thread size, material, operating pressure and fluid, and HGW can return a sample part number, CAD file and price. Contact HGW Hydraulics for technical consultation and quotation.

References & standards used in this guide: ISO 228-1 (parallel pipe threads), British Standard Whitworth history, manufacturer technical notes on port assemblies, and the Parker O-Ring handbook for sealing/groove design. For final design and procurement, always consult up-to-date ISO/EN standards and supplier datasheets.