What Does NPT Mean in Plumbing?

In plumbing, hydraulic systems, and industrial piping, one of the most common thread standards you will encounter is National Pipe Thread (NPT). Recognized for its tapered design and effective sealing properties, NPT has been a cornerstone in North American pipe connection technology for over a century. For engineers, technicians, and suppliers—such as HGW Hydraulic—understanding NPT threads is essential for ensuring compatibility, leak prevention, and long-term system reliability.

The Origins of NPT

The NPT standard was first established in the mid-19th century as industrial plumbing and steam systems expanded in the United States. To address issues of leakage and incompatible fittings, the American National Standard Pipe Thread system was developed and later codified under ANSI/ASME B1.20.1. Since then, NPT has remained the dominant standard in North America and is also used in various global markets, particularly in oil, gas, water treatment, and hydraulic sectors.

Technical Design of NPT Threads

NPT threads are defined by several key characteristics that give them their sealing ability:

- Tapered Profile: The diameter decreases at a rate of 1:16, allowing threads to wedge tightly when assembled.

- Thread Angle: NPT uses a 60° thread angle for consistent engagement.

- Flat Crest and Root: This helps improve sealing contact and mechanical strength.

- Interference Fit: The taper ensures that the male and female threads compress together, creating a seal without relying solely on a gasket or O-ring.

Common Materials for NPT Fittings

NPT threads are manufactured in a wide range of materials to suit different environments:

- Brass: Corrosion-resistant, ideal for water, air, and low-pressure systems.

- Carbon Steel: Common in industrial and hydraulic systems where high strength is required.

- Stainless Steel: Provides excellent corrosion resistance for chemical and marine applications.

- PVC & CPVC: Used for non-metallic piping in water and chemical handling.

- Aluminum: Lightweight option for certain pneumatic and specialty applications.

NPT Size Specifications

NPT threads are not measured by outer diameter alone; instead, their size refers to the nominal pipe size (NPS). This can be confusing for new users, as the actual thread diameter is larger than the NPS designation. Below is a reference chart for common NPT sizes:

| NPT Size | Threads Per Inch (TPI) | Major Diameter (inches) | Major Diameter (mm) |

|---|---|---|---|

| 1/8" | 27 | 0.405 | 10.29 |

| 1/4" | 18 | 0.540 | 13.72 |

| 3/8" | 18 | 0.675 | 17.15 |

| 1/2" | 14 | 0.840 | 21.34 |

| 3/4" | 14 | 1.050 | 26.67 |

| 1" | 11.5 | 1.315 | 33.40 |

Sealing Methods for NPT Connections

While NPT’s tapered design creates a strong mechanical seal, it is not inherently leak-proof under all conditions. To ensure leak-free performance, the following sealing techniques are commonly used:

- PTFE Tape: Applied clockwise to the male threads to fill micro-gaps and provide additional sealing.

- Pipe Dope: A liquid sealant that also lubricates threads, making assembly easier.

- Combination: For high-pressure hydraulic or gas systems, both tape and dope may be used together.

Advantages of NPT Threads in Plumbing

- Simple design and easy to machine

- Compatible with a wide variety of materials

- Strong mechanical connection

- Widely available in North America

- Suitable for both low- and high-pressure applications (with correct sealing)

Limitations of NPT Threads

Despite its popularity, NPT has certain limitations engineers should consider:

- Not self-sealing—requires sealant or tape

- Potential for thread galling in stainless steel

- Not ideal for frequent disassembly and reassembly

- Thread taper can cause stress in thin-walled fittings

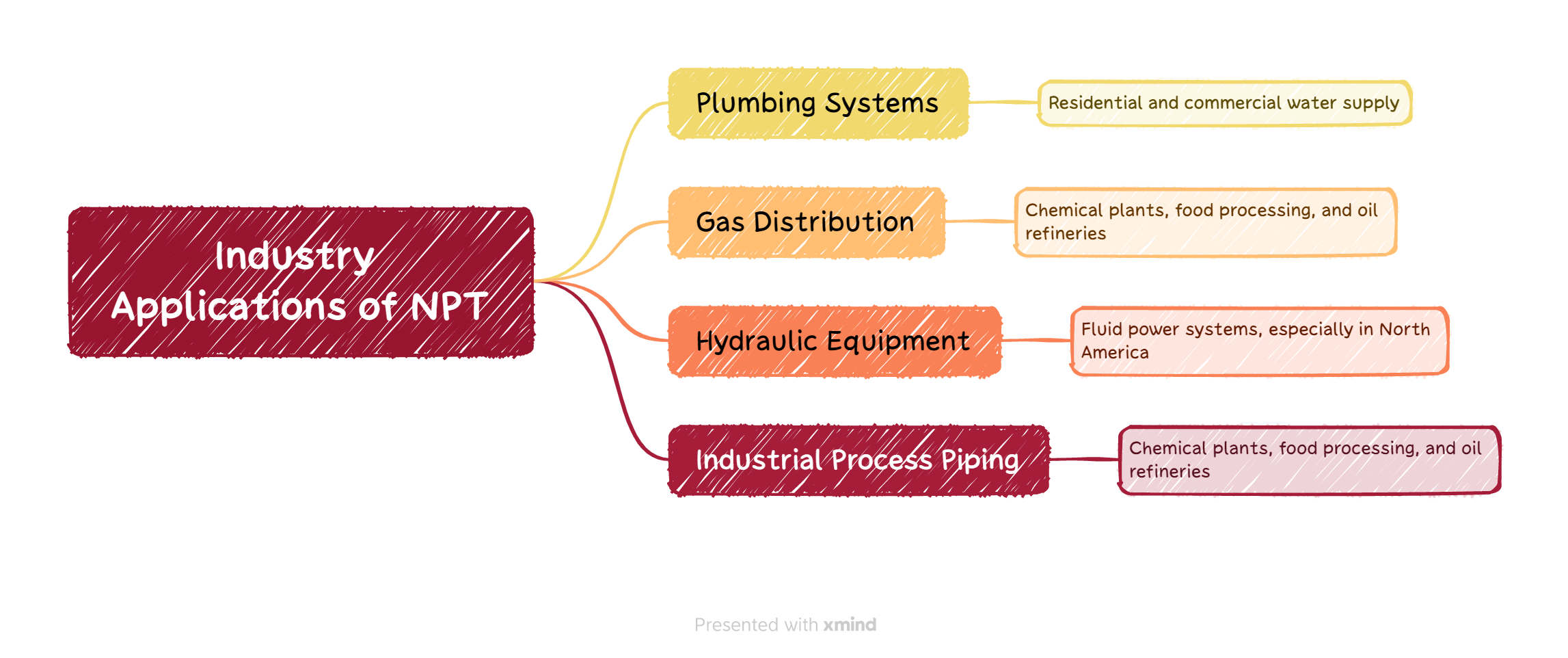

Industry Applications of NPT

NPT threads are found across multiple sectors:

- Plumbing Systems: Residential and commercial water supply

- Gas Distribution: Natural gas, propane, and compressed air systems

- Hydraulic Equipment: Fluid power systems, especially in North America

- Industrial Process Piping: Chemical plants, food processing, and oil refineries

HGW Hydraulic’s Expertise in NPT-Compatible Components

HGW Hydraulic manufactures precision-engineered fittings, adapters, and connectors designed to work with NPT threads in demanding environments. Our products undergo rigorous testing for dimensional accuracy, pressure resistance, and corrosion protection. Whether for OEM hydraulic machinery, industrial retrofits, or custom fluid handling systems, HGW ensures that every NPT-compatible product meets international quality standards.

Best Practices for Installing NPT Fittings

- Clean all threads before assembly to remove debris and oil.

- Apply sealant properly—too much can cause hydraulic contamination.

- Tighten gradually, avoiding over-torque that may crack fittings.

- Pressure-test before full operation to confirm sealing performance.

- Inspect connections regularly in high-vibration systems.

Conclusion

National Pipe Thread (NPT) remains a versatile and reliable thread standard in plumbing and hydraulics. By understanding its technical features, proper installation techniques, and material compatibility, you can ensure optimal performance in any application. For high-quality, precision NPT fittings designed for demanding environments, HGW Hydraulic is a trusted partner for both standard and custom solutions.

-

2025 Shanghai Bauma Exhibition China International Construction Machinery ExhibitionUpdate on 2024-12-25

-

2025 Las Vegas International Mining ExhibitionUpdate on 2024-12-25

-

Leading the High-End and Empowering the World | Bauma China 2025, Hgw Successfully ConcludedUpdate on 2024-12-25

-

Hgw's Multi-field Hydraulic Products Appeared at the Exhibition丨MINEXPOUpdate on 2024-12-25

-

2025 PTC ASIAUpdate on 2025-02-12

-

Top 10 Leading Hydraulic Fitting Companies in the World[2025 Updated]Update on 2025-02-27

-

Top 10 Global Suppliers of Hydraulic Hose FittingsUpdate on 2025-03-04

-

HGW's O-Ring Face Seal Fittings(ORFS): From Core to Best UseUpdate on 2025-03-08