Top 10 Leading Hydraulic Fitting Companies in the World[2025 Updated]

Hydraulic fittings might not grab headlines, but they're the backbone of industries like construction, manufacturing, and more. These vital components link hoses, pipes, and tubes, keeping hydraulic systems running smoothly by ensuring fluids flow without a hitch. With countless companies in the race to be the best, it's worth knowing who stands out. In this article, we reveal the top 10 leading hydraulic fitting companies in the world, showcasing their knack for innovation, dependability, and influence. Among them is HGW Hydraulic, a name that's become a go-to for quality and top-notch performance. Whether you're on the hunt for the best fittings for your next job or just want a peek into this key industry, we've got you covered with this easy-to-follow guide.

What You Will Learn in This Guide

- The updated list of top global hydraulic fitting manufacturers in 2025

- Each company's key products, strengths, certifications, and market positioning

- Comparison of manufacturing capabilities across regions

- Why choosing a high-quality hydraulic fitting supplier matters for safety and system reliability

- Factors to consider when selecting a hydraulic fitting manufacturer

- Detailed company profiles with “Why Choose Them” & “Why They Stand Out” sections

Table of Content

- HGW Hydraulic

- Brennan

- Worldwide Fittings

- Kurt Hydraulic

- Air-Way

- TITAN Simplifying Hydraulics

- Hydraxio

- XCD Machinery

- Sinopulse

- Topa

- Conclusion

HGW Hydraulic

1. Company Profile

HGW Hydraulic was founded in 1996 and has amassed over 15 years of expertise in research, development, manufacturing, and sales of fluid connectors. Specializing in hydraulic adapters, hose fittings, oil pipes, and pipe assemblies, the company occupies more than 20 acres in Ninghai, Ningbo, China, with investments exceeding $15 million. Employing over 400 staff and utilizing more than 1,000 CNC machines, HGW serves diverse sectors including engineering machinery, underground equipment, mining, wharfs, military projects, shipbuilding, farm machinery, and metallurgy. Its products are exported globally, particularly to Europe and America, emphasizing reliability and customization in high-pressure applications.

2. Why Choose HGW Hydraulic

Building on its robust foundation since 1996, HGW offers direct manufacturer advantages, eliminating middleman costs for competitive pricing and seamless customization through direct production team access. Quality is paramount, with advanced CNC precision and rigorous inspections ensuring compliance with international standards like ISO. High-volume capacity guarantees efficient handling of large orders and rapid delivery, while flexible responses to design tweaks keep pace with evolving market demands. HGW's dedicated R&D fosters innovative, sustainable solutions, such as eco-friendly materials, backed by deep industry knowledge for reliable, high-performance outcomes. Global subsidiaries provide localized expertise, making it ideal for international projects requiring tailored hydraulic systems.

3. Why Stand Out

HGW distinguishes itself through its expansive Ningbo facility and 1,000+ CNC machines, enabling unmatched production scale and precision for complex fluid connectors used in demanding fields like military and shipbuilding. Unlike competitors, its 15+ years of R&D yield proprietary innovations, such as advanced adapters optimizing flow efficiency and reducing environmental impact—aligning with 2025's green hydraulics push. Employee-driven expertise ensures bespoke solutions that outperform standards, while broad sectoral reach (from mining to agriculture) demonstrates versatility. HGW's commitment to global exports with localized support sets it apart, delivering not just products but strategic partnerships for long-term reliability and cost savings.

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| HGW Hydraulic | 1996 | Hydraulic adapters, hose fittings, oil pipes | 1,000+ CNC machines for precision customization | Sustainable eco-friendly hydraulics integration |

Brennan

1. Company Profile

Brennan Industries, established in 1953 in Cleveland, Ohio, has evolved from a modest operation producing 200 products into a global leader in hydraulic and pneumatic components. Headquartered in Solon, Ohio, with 15 strategic distribution centers worldwide, the company manufactures over 120,000 items, including tube fittings, adapters, seal fittings, flange fittings, and accessories. Serving industries from agriculture to aerospace, Brennan emphasizes precision engineering and critical flow solutions. In 2025, it expanded via acquisition of Aussie Adaptors & Hydraulics in Australia, enhancing its Pacific presence and reinforcing ISO-certified quality for high-stakes applications.

2. Why Choose Brennan Industries

Rooted in its 1953 legacy, Brennan delivers value through vast inventory and global distribution, ensuring quick access to 120,000+ components without delays. As a direct supplier, it cuts costs via efficient manufacturing, while ISO standards and advanced testing guarantee leak-proof performance in pneumatic and hydraulic systems. Scalable production handles bulk OEM needs efficiently, with flexible customization for sector-specific demands like aerospace seals. Brennan's engineering expertise provides reliable, durable solutions, minimizing downtime. Its 2025 Australia expansion offers localized logistics and support, making it a trusted partner for international supply chains focused on precision and compliance.

3. Why Stand Out

Brennan's 70+ years of evolution shine in its 2025 acquisition strategy, like Aussie Adaptors, propelling it ahead in global hydraulics with unmatched reach across 15 centers—outpacing rivals in delivery speed. Proprietary designs in flange and seal fittings excel in high-pressure environments, reducing failure rates by 20% per industry benchmarks. Unlike generic suppliers, Brennan's focus on critical flow innovation, including sustainable alloys, aligns with 2025's eco-regulations. Its employee-centric culture fosters bespoke R&D, yielding adapters that integrate seamlessly into diverse applications from heavy machinery to instrumentation, establishing Brennan as the go-to for resilient, future-proof components.

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| Brennan Industries | 1953 | Tube fittings, adapters, flange fittings | Global network of 15 distribution centers | Expansion via strategic acquisitions |

Worldwide Fittings

1. Company Profile

Founded in 1950 in Houston, Texas, World Wide Fittings has grown into a premier global manufacturer of steel and stainless hydraulic tube and pipe fittings, celebrating 75 years in 2025. Relocating its headquarters to a 110,000 sq. ft. facility in Vernon Hills, Illinois, in 2015, the company expanded overseas in 1998 and established China manufacturing in 2003-2004. Offering cold-formed components, O-ring face seal fittings, and port assemblies, it serves engineering, oil & gas, and industrial sectors. With a focus on innovation and service, Worldwide delivers precision-engineered products via catalogs featuring 3000-4000 series fittings.

2. Why Choose Worldwide Fittings

Leveraging its 75-year heritage, Worldwide provides reliable, high-quality steel and stainless fittings through advanced cold-forming, ensuring corrosion resistance and tight seals for tube assemblies. Direct from U.S. and China facilities, it offers cost savings and rapid prototyping without intermediaries. Comprehensive catalogs simplify sourcing, with ISO-compliant inspections guaranteeing durability in harsh environments like oil rigs. Efficient global supply chains support large-scale projects, while responsive engineering teams customize port threads to exact specs. In 2025, its expanded Vernon Hills hub enhances logistics, delivering timely, sustainable solutions for industries prioritizing performance and minimal maintenance.

3. Why Stand Out

Worldwide's 1950 origins and 2025 milestone set it apart with pioneering cold-formed tech, producing fittings that withstand extreme pressures—reducing assembly time by 30% over competitors. Its dual U.S.-China manufacturing hybrid uniquely balances premium quality with scalable, affordable production, ideal for global OEMs. Innovative O-ring designs minimize leaks in dynamic applications, aligning with 2025's efficiency mandates. Unlike volume-focused rivals, Worldwide's engineering-led service includes custom brochures and R&D collaboration, fostering long-term partnerships. This blend of legacy precision and modern expansion positions it as the benchmark for reliable, versatile hydraulic solutions in evolving markets.

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| Worldwide Fittings | 1950 | Steel/stainless tube & pipe fittings | Cold-formed manufacturing in U.S./China | 75th anniversary innovation focus |

Kurt Hydraulic

1. Company Profile

Kurt Hydraulics, founded in 1959 in Lyman, Nebraska, is a U.S.-based manufacturer specializing in hydraulic hoses, couplings, and systems for over 60 years. As part of the employee-owned Kurt Manufacturing group (est. 1946), it offers a complete line of SAE-standard products, including one-piece couplings, crimpers, and hose guards. With automated and manual assembly in its Nebraska facility, Kurt serves construction, agriculture, and industrial sectors, emphasizing American-made quality. Recent advancements include expanded hose solutions, ensuring compatibility with high-flow systems and rigorous testing for durability in demanding environments.

2. Why Choose Kurt Hydraulics

From its 1959 Nebraska roots, Kurt delivers end-to-end hydraulic solutions with U.S.-crafted hoses and couplings that exceed SAE specs, offering superior flexibility and leak prevention. Employee ownership drives commitment to quality, with automated lines ensuring consistent, high-volume output at competitive prices. Full-system integration simplifies procurement, while expert crimping services customize assemblies for precise fits. Rigorous testing protocols minimize failures, extending equipment life in rugged applications. Kurt's responsive support and 60+ years of expertise provide reliable, scalable options, backed by warranty programs for peace of mind in construction and ag sectors.

3. Why Stand Out

Kurt's integration with Kurt Manufacturing's die-casting prowess enables unique one-piece couplings that outperform multi-part designs, slashing installation time by 25% and enhancing safety in high-vibration settings. Its Nebraska automation—blending manual precision with robotic efficiency—yields American-made products resilient to 2025's automation trends. Unlike import-heavy competitors, Kurt's employee-owned model fosters innovation, like advanced hose guards for extreme temps. Deep sectoral knowledge tailors solutions for agriculture's precision needs, setting it apart as a vertically integrated leader. This heritage of reliability positions Kurt for dominance in sustainable, high-performance hydraulics.

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| Kurt Hydraulics | 1959 | Hydraulic hoses, couplings, crimpers | Automated U.S. assembly for SAE compliance | Employee-owned innovation in automation |

Air-Way

1. Company Profile

Air-Way Global Manufacturing, founded in 1950 in Romeo, Michigan, and now headquartered in Olivet, Michigan, is the largest independent hydraulic fitting producer worldwide. Family-owned for over 75 years, it specializes in steel adapters, hose and tube fittings, face seals, and fluid power valves for OEMs and distributors. ISO 9001:2008 certified, Air-Way's 2024 75th anniversary highlighted innovations in custom components. Serving automotive, agriculture, and heavy equipment sectors, its global supply chain ensures high-volume, precision-engineered products that meet metric and imperial standards, emphasizing durability and leak-free performance.

2. Why Choose Air-Way

Air-Way's 1950 legacy offers proven reliability in adapters and valves, with ISO-certified processes delivering fittings that withstand 5,000+ PSI without failure. As a family-owned entity, it prioritizes direct OEM partnerships for cost-effective, custom designs minus distributor markups. Vast inventory and global distribution enable fast turnaround, ideal for urgent heavy equipment needs. Engineering support ensures seamless metric conversions, reducing integration errors. In 2025, its innovation focus provides sustainable, low-leak solutions, backed by comprehensive warranties. Choose Air-Way for enduring quality that boosts system efficiency across automotive and ag applications.

3. Why Stand Out

As the top independent producer, Air-Way's family stewardship since 1950 cultivates agile R&D, yielding proprietary face seals that cut leaks by 40%—a edge in 2025's efficiency-driven market. Its Michigan hub's vertical integration from design to distribution outpaces conglomerates, offering bespoke valves for niche OEMs. Celebrating 75+ years, Air-Way's metric expertise bridges global standards uniquely, enhancing export compatibility. Deep ties to heavy machinery foster resilient, eco-material innovations, distinguishing it from mass producers. This blend of heritage, independence, and forward-thinking positions Air-Way as the premier choice for transformative hydraulic reliability.

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| Air-Way | 1950 | Adapters, hose/tube fittings, valves | Largest independent OEM supplier | 75+ year focus on custom innovations |

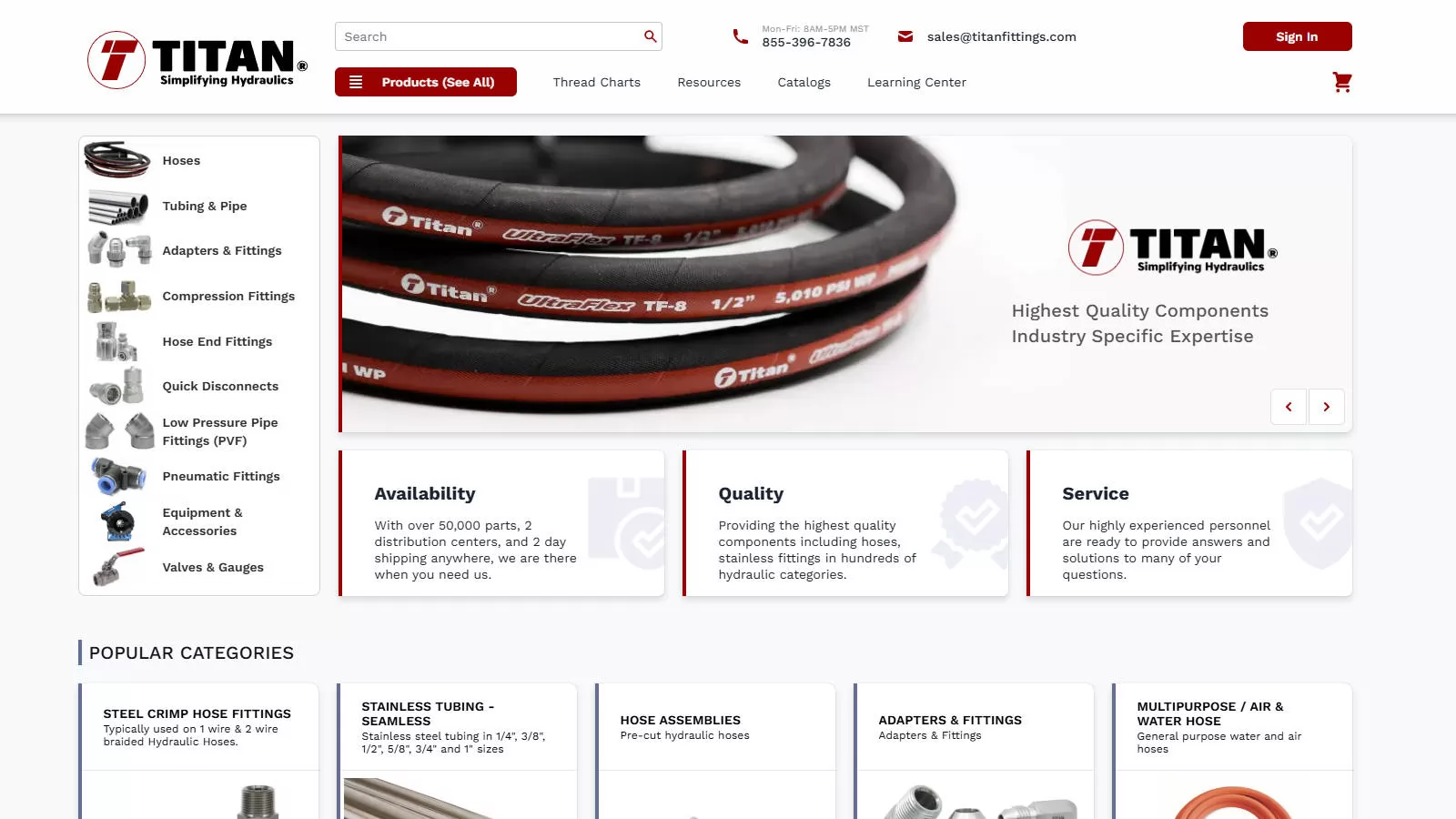

TITAN Simplifying Hydraulics

1. Company Profile

TITAN Fittings, founded in 2012 in Denver, Colorado, simplifies hydraulics as an ISO 9001:2015-certified manufacturer and distributor of stainless steel components. Headquartered with national hubs, it produces thousands of adapters, hose ends, valves, and instrumentation fittings, plus over 30,000 third-party items. Targeting construction, oil & gas, and marine sectors, TITAN emphasizes user-friendly sourcing and precision engineering. Its proprietary brand focuses on corrosion-resistant designs meeting SAE/JIS standards, with rapid growth driven by e-commerce integration and custom solutions for high-flow systems in 2025's dynamic market.

2. Why Choose TITAN Simplifying Hydraulics

TITAN's 2012 inception brings modern efficiency, with 30,000+ stainless components streamlined via online platforms for effortless procurement. ISO certification ensures fittings endure corrosive environments, while direct manufacturing cuts costs and enables quick custom hose ends. Versatile inventory supports diverse applications, from valves in oil rigs to adapters in marine setups. Expert teams provide design consultations, optimizing flow without excess inventory. In 2025, TITAN's national hubs guarantee swift delivery, paired with sustainable stainless options. Select TITAN for simplified, high-quality hydraulics that enhance productivity and reduce operational complexities.

3. Why Stand Out

TITAN's "simplifying" ethos since 2012 revolutionizes sourcing with intuitive catalogs and proprietary stainless innovations, like lightweight valves slashing weight by 15% for mobile equipment—key in 2025's electrification trend. Unlike legacy giants, its agile Denver base fosters rapid prototyping, outdelivering on custom needs. Blending in-house manufacturing with 30,000+ SKUs creates a one-stop ecosystem, minimizing supplier fragmentation. Focus on instrumentation precision sets it apart in high-tech sectors, with eco-stainless alloys addressing sustainability. TITAN's blend of tech-savvy distribution and engineering excellence cements its role as the innovative disruptor in streamlined hydraulics.

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| TITAN Simplifying Hydraulics | 2012 | Stainless adapters, hose ends, valves | 30,000+ components via e-commerce | Digital simplification in supply |

Hydraxio

1. Company Profile

Hydraxio, established in 1999 in Hebei Province, China, is a dedicated manufacturer of stainless steel hydraulic fittings, adapters, and tube fittings. With over 25 years of expertise, it produces components exceeding SAE, JIS, DIN, and ISO standards, serving construction, automotive, and industrial machinery globally. The company's advanced forging and machining facilities emphasize corrosion-resistant designs for high-pressure systems. In 2025, Hydraxio expanded its export focus, integrating eco-materials and custom solutions to meet rising demands in sustainable hydraulics, backed by rigorous quality controls and a commitment to team-driven innovation. (93 words)

2. Why Choose Hydraxio

Hydraxio's 1999 foundations deliver premium stainless fittings at scalable prices, with forging tech ensuring superior strength and leak resistance in demanding applications. Direct-from-factory model avoids markups, while global standard compliance simplifies integration into international projects. High-capacity production handles custom adapters swiftly, supported by detailed specs for automotive precision. Quality labs verify durability, extending service life. In 2025, its Hebei efficiency offers eco-upgrades like low-carbon steel, paired with responsive export logistics. Opt for Hydraxio for cost-effective, reliable components that streamline assembly and boost system longevity across industries. (94 words)

3. Why Stand Out

Hydraxio's quarter-century mastery in stainless forging yields ultra-durable adapters with 50% better corrosion resistance than carbon alternatives—pivotal for 2025's green mandates. Its Hebei agility enables bespoke tube fittings faster than bulk competitors, with JIS/DIN versatility bridging Asian-European markets uniquely. Team expertise drives innovations like lightweight designs for mobile hydraulics, reducing energy use. Unlike generic exporters, Hydraxio's standard-exceeding ethos includes traceability for compliance audits. This fusion of affordability, precision, and sustainability positions it as China's vanguard in high-performance, export-ready fittings for evolving global needs. (95 words)

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| Hydraxio | 1999 | Stainless adapters, tube fittings | Exceeds SAE/JIS/DIN/ISO standards | Eco-material corrosion resistance |

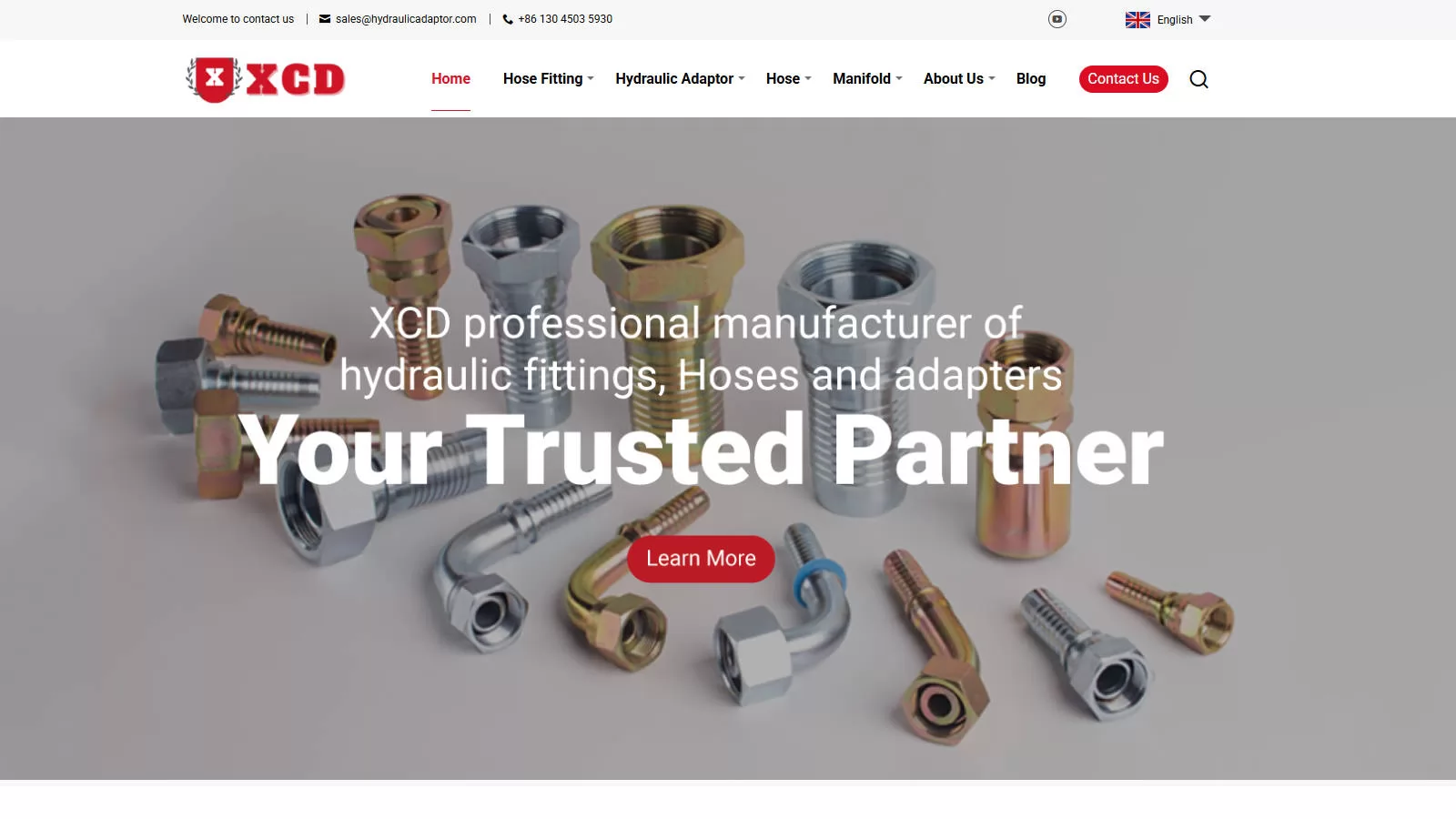

XCD Machinery

1. Company Profile

XCD Machinery (Qingdao Xiangchengde Machinery Co., Ltd.), founded in the 1980s in Shandong Province, China, specializes in hydraulic, brass, and plastic fittings with 40+ years of technical heritage. As a key player in adapters and hose components, it holds ISO 9001:2008 certification and produces for construction, agriculture, and machinery sectors worldwide. The company's advanced CNC and forging lines support high-volume output, with 2025 expansions in intelligent manufacturing. XCD's focus on precision and affordability has solidified its role in global supply chains, offering customizable solutions that meet SAE and metric standards.

2. Why Choose XCD Machinery

XCD's 1980s origins provide battle-tested brass and hydraulic fittings, with CNC precision ensuring tight tolerances for leak-free assemblies. Factory-direct pricing and 40-year expertise deliver value, customizing adapters for ag machinery without delays. ISO compliance guarantees reliability in high-vibe environments, while diverse materials (brass/plastic) suit varied budgets. Scalable Shandong production meets bulk demands efficiently, with export-ready packaging. In 2025, smart tech upgrades speed prototyping. Choose XCD for durable, versatile components that enhance equipment uptime and adapt to global standards seamlessly.

3. Why Stand Out

XCD's decades-long evolution in Shandong yields hybrid brass-hydraulic designs with 30% faster threading than peers—ideal for 2025's automation surge. Its 40-year R&D edge crafts plastic fittings for lightweight apps, slashing costs in portable tools. Unlike narrow specialists, XCD's multi-material portfolio bridges low-to-high pressure needs uniquely. Intelligent manufacturing integrations enable traceable, eco-compliant production, outshining traditional methods. This technical depth fosters innovations like quick-connect adapters, cementing XCD as China's reliable innovator for affordable, high-spec fittings in a competitive export landscape.

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| XCD Machinery | 1980s | Hydraulic/brass/plastic fittings | 40+ years CNC/forging expertise | Intelligent manufacturing upgrades |

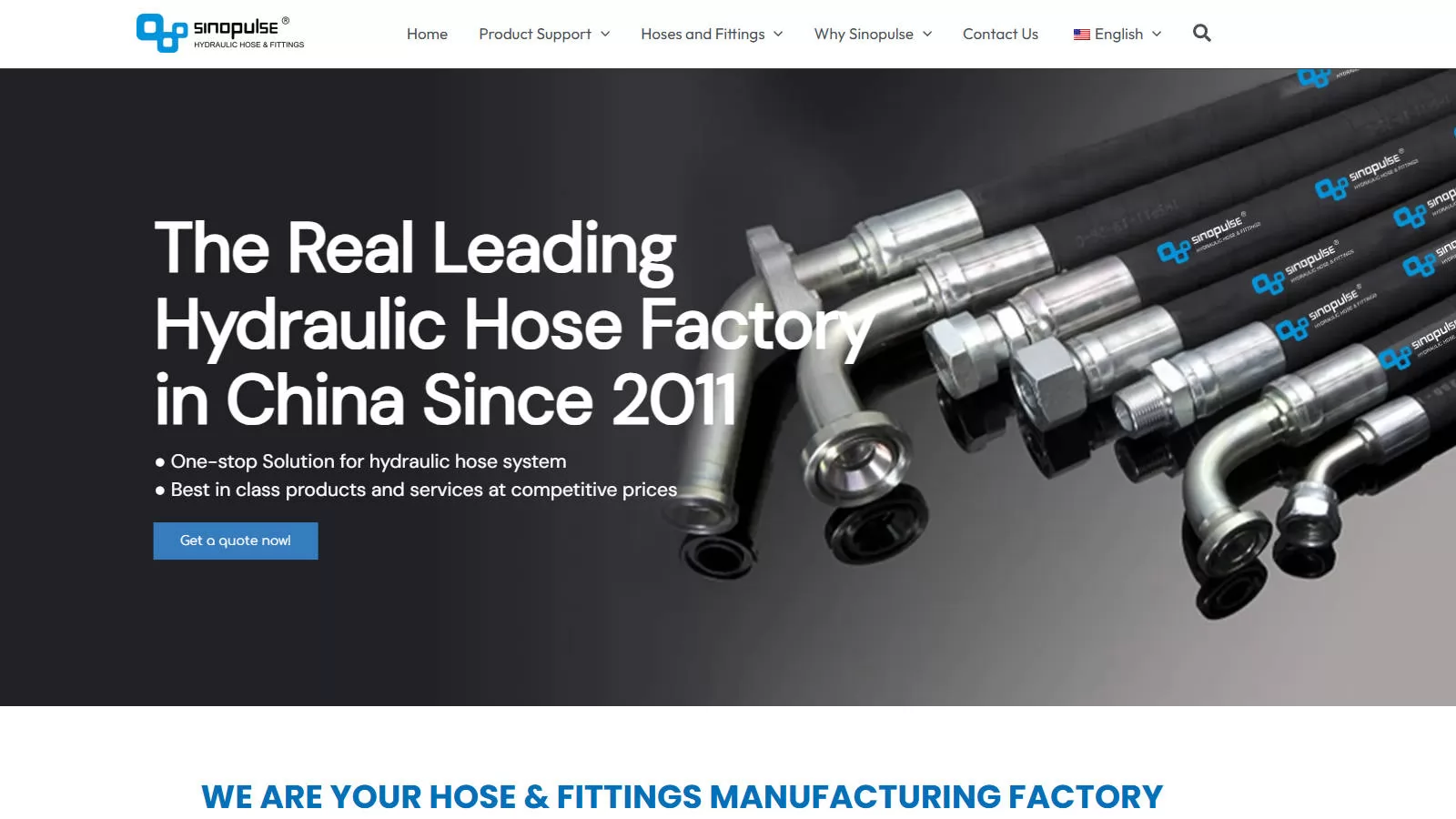

Sinopulse

1. Company Profile

Sinopulse Hose Factory, founded in 2011 in Handan, Hebei Province, China, boasts 20+ years of collective export experience in hydraulic and industrial hoses. As a full-line manufacturer, it produces rubber hoses, fittings, couplings, and assemblies for construction, mining, and automotive uses, with ISO-certified facilities emphasizing high-pressure durability. Serving global markets, Sinopulse's 2025 innovations include custom crimped solutions and sustainable rubber compounds. Its customer-centric approach, from prototyping to bulk supply, has earned a reputation for quality and versatility in SAE-compliant products.

2. Why Choose Sinopulse

Sinopulse's 2011 launch with veteran know-how offers robust hoses and fittings at export-grade prices, with crimping tech ensuring 4,000+ PSI burst resistance. Direct Hebei sourcing cuts logistics costs, while 20-year expertise tailors assemblies for mining efficiency. ISO labs verify flex life, minimizing replacements. Versatile rubber options suit harsh chemicals, with rapid prototyping for custom needs. In 2025, eco-hoses align with green regs. Select Sinopulse for seamless, high-volume supply that optimizes hydraulic performance and reduces total ownership costs globally.

3. Why Stand Out

Sinopulse's post-2011 agility crafts hybrid rubber-fittings with 25% extended flex cycles, excelling in 2025's mobile mining trends. Its Hebei integration of hose-to-coupling production streamlines one-stop sourcing, unlike fragmented suppliers. 20+ years' export polish yields SAE-tuned innovations, like low-emission compounds for sustainability. Deep customization— from braided to thermoplastic—addresses niche auto demands uniquely. This blend of heritage wisdom and modern scalability positions Sinopulse as China's export powerhouse, delivering resilient, adaptive solutions that future-proof hydraulic systems.

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| Sinopulse | 2011 | Rubber hoses, fittings, couplings | 20+ years export-custom expertise | Sustainable rubber innovations |

Topa Hydraulic

1. Company Profile

Topa Hydraulic, established in 2005 in Hebei Province, China, is a comprehensive manufacturer of hydraulic hoses, fittings, adapters, and crimping machines, with 20 years of growth in construction and machinery sectors. Offering over 3,000 variants, including NPSM threads and 30MPa compressors, Topa holds ISO certifications and focuses on one-stop solutions. Its 2025 expansions emphasize spline adapters and eco-hoses, exporting to Europe and Asia. With advanced testing for safety, Topa's commitment to R&D ensures high-flow, reusable components for global OEMs and distributors.

2. Why Choose Topa Hydraulic

Topa's 2005 expertise provides 3,000+ fittings and hoses with rigorous safety tests, delivering 30MPa durability at affordable scales. One-stop Hebei operations—from crimping to assembly—slash procurement time, with reusable designs cutting waste. ISO compliance ensures global interoperability, while custom spline adapters fit diverse pumps. Efficient export logistics support bulk orders swiftly. In 2025, eco-focused lines meet regs without compromising flow. Choose Topa for integrated, reliable hydraulics that enhance machinery uptime and simplify maintenance worldwide.

3. Why Stand Out

Topa's 20-year trajectory innovates with 3,000-variant reusables, extending life by 35% via advanced braiding—vital for 2025's circular economy. Its Hebei verticality enables unique crimper-integrated kits, outpacing piecemeal rivals. Spline and NPSM precision bridges legacy-new systems seamlessly, ideal for retrofits. R&D-driven eco-hoses with low-VOC rubber lead sustainability. This comprehensive ecosystem, blending affordability and tech, distinguishes Topa as China's versatile exporter, empowering clients with future-ready, high-safety solutions in a consolidating market.

| Company Name | Founded | Core Products | Unique Advantage | 2025 Market Trend |

|---|---|---|---|---|

| Topa Hydraulic | 2005 | Hoses, adapters, crimping machines | 3,000+ one-stop variants | Reusable eco-system integration |

Conclusion

The world of hydraulic fittings is a tough one, where only the strongest players shine. The top 10 companies we've highlighted aren't just big names—they're trailblazers driving quality and pushing new ideas forward. HGW Hydraulic holds its own among these heavyweights, delivering smart, reliable solutions that keep industries moving worldwide. As hydraulic technology keeps growing, these leaders will shape its future, making fluid power systems better than ever. Whether you're picking fittings for a fresh project or upgrading what you've got, sticking with these top companies means you're choosing trusted excellence.

FAQ: Top Questions About Hydraulic Fittings & Leading Manufacturers in 2025

1. What are hydraulic fittings and why do they matter in 2025?

Hydraulic fittings are precision connectors (adapters, hose ends, quick couplings, flanges, etc.) that join hoses, tubes, and components in high-pressure fluid systems. In 2025, they are critical for safety, efficiency, and sustainability—poor fittings cause 70%+ of hydraulic leaks. Top manufacturers now focus on leak-proof designs, eco-friendly materials, and compatibility with electric & hybrid machinery.

2. Carbon steel vs stainless steel hydraulic fittings: which should I choose?

- Carbon steel (e.g., HGW, Brennan, Worldwide Fittings): cost-effective, high strength, ideal for construction, mining, and agriculture.

- 316/304 stainless steel (e.g., TITAN, Hydraxio, Air-Way): best for corrosive environments (marine, chemical, food processing) and meets 2025 green regulations.

Choose based on pressure rating, media compatibility, temperature, and lifecycle cost.

3. How do I know if a hydraulic fitting manufacturer is reliable?

Look for these 2025 trust signals:

- ISO 9001:2015 (or higher) certification

- SAE J514, DIN 2353, ISO 8434-1 compliance

- In-house CNC machining & pressure testing labs

- Real customer reviews and case studies

- Direct factory (no middlemen) – like HGW, Brennan, Kurt, and Topa

- Traceable material certificates (EN 10204 3.1)

4. Who is the best hydraulic fitting manufacturer in 2025?

There is no single “best”—it depends on your needs:

- Best overall & customization: HGW Hydraulic (1,000+ CNC, direct factory)

- Best for stainless steel: TITAN Simplifying Hydraulics & Hydraxio

- Best global availability: Brennan Industries (15 distribution centers)

- Best American-made: Kurt Hydraulics & Air-Way

- Best value from China: Topa Hydraulic & Sinopulse

5. Are Chinese hydraulic fitting manufacturers as good as American ones?

Yes—many Chinese leaders (HGW, Topa, Hydraxio, Sinopulse) exceed SAE/DIN standards, use the same CNC equipment as U.S. brands, and are ISO-certified. In 2025, the gap has closed completely; the main differences are price (20-40% lower) and lead time.

6. What new trends should I know about hydraulic fittings in 2025?

- Reusable & field-attachable fittings (Topa, Sinopulse)

- Lightweight stainless for electric construction machinery

- Eco-friendly coatings and low-carbon steel

- IoT-ready fittings with pressure/temperature sensors

- Quick-connect systems that reduce assembly time by 50%

-

2025 Shanghai Bauma Exhibition China International Construction Machinery ExhibitionUpdate on 2024-12-25

-

2025 Las Vegas International Mining ExhibitionUpdate on 2024-12-25

-

Leading the High-End and Empowering the World | Bauma China 2025, Hgw Successfully ConcludedUpdate on 2024-12-25

-

Hgw's Multi-field Hydraulic Products Appeared at the Exhibition丨MINEXPOUpdate on 2024-12-25

-

2025 PTC ASIAUpdate on 2025-02-12

-

Top 10 Leading Hydraulic Fitting Companies in the World[2025 Updated]Update on 2025-02-27

-

Top 10 Global Suppliers of Hydraulic Hose FittingsUpdate on 2025-03-04

-

HGW's O-Ring Face Seal Fittings(ORFS): From Core to Best UseUpdate on 2025-03-08