NPT vs NPSM: Choosing the Right Thread for Leak-Free Hydraulics

Table of Contents

- Introduction to Hydraulic Threading Standards

- Understanding the Basics: NPT and NPSM Defined

- Key Differences Between NPT and NPSM Threads

- Leak Prevention: Why Thread Choice Matters

- Sealing Methods for NPT vs NPSM Connections

- Application Guide: When to Use NPT vs NPSM

- Installation Best Practices for Leak-Free Connections

- Troubleshooting Common Leakage Issues

- Industry Standards and Compliance Considerations

- Conclusion: Making the Right Thread Choice

Introduction to Hydraulic Threading Standards

In hydraulic systems, the integrity of connections is paramount. A single leak can lead to system failure, reduced efficiency, environmental contamination, and even catastrophic accidents. At the heart of these connections are threading standards that determine how components fit together.

Two of the most commonly confused threading standards in North American hydraulic systems are NPT (National Pipe Taper) and NPSM (National Pipe Straight Mechanical) threads. Despite their similar acronyms and appearances, these threading systems serve different purposes and offer distinct advantages and limitations, particularly regarding leak prevention.

The distinction between NPT and NPSM is not merely academic—it has practical implications for system designers, maintenance personnel, and hydraulic system operators. Selecting the wrong thread type can result in immediate leaks, progressive failures, and unnecessary downtime.

Why This Matters: According to industry data, up to 80% of hydraulic system failures can be traced back to fluid leakage issues, with improper fitting selection and installation being primary contributors. Understanding the differences between NPT and NPSM threads is essential for developing and maintaining leak-free hydraulic systems.

In this comprehensive guide from HGW Hydraulic, we'll examine the critical differences between NPT and NPSM threads, explore their appropriate applications, and provide practical guidance for selecting the right thread type to ensure leak-free hydraulic operations.

Understanding the Basics: NPT and NPSM Defined

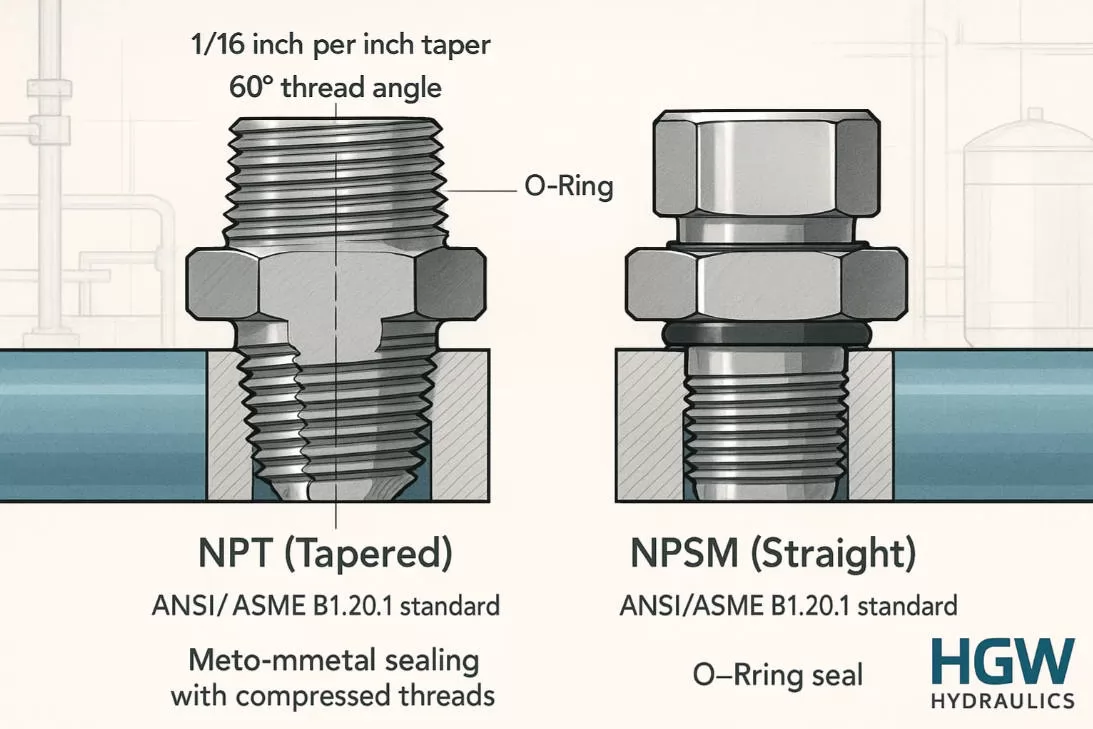

What is NPT (National Pipe Taper)?

NPT, or National Pipe Taper, is one of the most widely used pipe thread standards in North America. As the name suggests, NPT features a tapered thread design with the following characteristics:

- Taper rate: 1/16 inch per inch (or 3/4 inch per foot) of thread length

- Thread angle: 60 degrees

- Standard: ANSI/ASME B1.20.1

- Sealing mechanism: Relies on deformation and metal-to-metal wedging action of the tapered threads

The tapered design of NPT threads means that as the fitting is tightened, the threads compress against each other, creating a mechanical seal. This design inherently provides a sealing function—the deeper the engagement, the tighter the seal.

What is NPSM (National Pipe Straight Mechanical)?

NPSM, or National Pipe Straight Mechanical, features straight (parallel) threads with these key characteristics:

- Taper rate: None (straight/parallel threads)

- Thread angle: 60 degrees

- Standard: ANSI/ASME B1.20.1

- Sealing mechanism: Requires a separate sealing element (usually an O-ring, gasket, or mechanical seal)

Unlike NPT, NPSM threads do not create a seal through thread engagement alone. Instead, they primarily provide mechanical connection, with sealing accomplished through supplementary means.

Important Distinction: The fundamental difference between NPT and NPSM is that NPT threads are tapered, creating a wedging action that contributes to sealing, while NPSM threads are straight and rely entirely on separate sealing mechanisms.

Key Differences Between NPT and NPSM Threads

Understanding the distinctive characteristics of NPT and NPSM threads is crucial for proper application in hydraulic systems. Let's examine their differences across several critical parameters:

| Feature | NPT (National Pipe Taper) | NPSM (National Pipe Straight Mechanical) |

|---|---|---|

| Thread Profile | Tapered (conical) threads | Straight (parallel) threads |

| Primary Sealing Mechanism | Thread deformation and metal-to-metal contact | Separate sealing element (O-ring, gasket) |

| Thread Engagement | Becomes progressively tighter as threaded deeper | Consistent engagement throughout |

| Pressure Rating | Generally higher pressure capability | Pressure limited by auxiliary sealing element |

| Installation Complexity | Moderate to high (requires proper torque and sealant) | Low to moderate (simpler alignment) |

| Reusability | Limited (thread deformation affects reusability) | Better (threads themselves don't deform) |

| Common Applications | High-pressure systems, permanent installations | Lower pressure applications, connections requiring frequent disassembly |

Thread Profile and Visual Identification

Visually distinguishing between NPT and NPSM threads can be challenging for the untrained eye. Here are some identification tips:

- NPT threads appear to narrow toward one end when observed closely.

- NPSM threads maintain consistent diameter throughout their length.

- A simple test: When mating a male NPT with a female NPSM, the connection will tighten initially but become loose before achieving a complete seal.

Thread Standards and Compatibility

Though both thread types fall under ANSI/ASME B1.20.1 standards, they are not directly interchangeable. Attempting to connect NPT with NPSM threads can lead to immediate leaks or progressive system failure under pressure.

Critical Note: Mixing NPT and NPSM threads is a common cause of persistent leaks in hydraulic systems. Always confirm thread compatibility before installation.

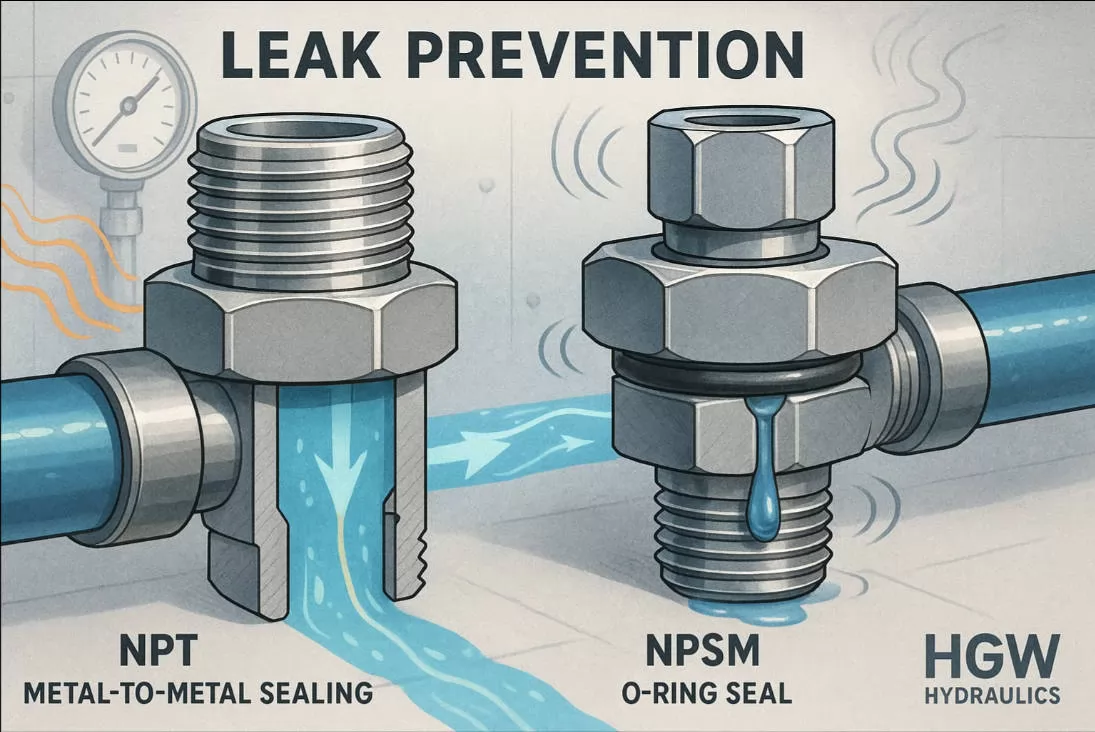

Leak Prevention: Why Thread Choice Matters

When it comes to hydraulic systems, preventing leaks is not just about operational efficiency—it's about safety, environmental protection, and cost control. The thread choice plays a pivotal role in leak prevention for several reasons:

Pressure Containment Capabilities

Hydraulic systems often operate at extremely high pressures—sometimes exceeding 5,000 PSI in heavy machinery applications. At these pressures, even minor flaws in thread selection or installation can lead to catastrophic failures.

- NPT threads create a mechanical seal that improves with pressure to a point. The tapered design means that as internal pressure increases, the forces pushing against the threads can actually enhance the seal integrity.

- NPSM threads rely entirely on the integrity of their sealing element. Under high pressure, these seals can extrude or deform if not properly supported by the thread design.

Thermal Cycling Considerations

Hydraulic systems frequently experience significant temperature fluctuations during operation:

- NPT connections may actually tighten further during thermal cycling as the metal expands and contracts, provided they were properly installed with thread sealant.

- NPSM connections depend on the thermal stability of their sealing elements, which may degrade over time with temperature fluctuations.

Vibration Resistance

Many hydraulic systems operate in environments with significant vibration:

- NPT threads resist vibration-induced loosening because of their wedging action and the use of thread sealants that act as thread-locking compounds.

- NPSM threads may require additional locking mechanisms to prevent loosening in high-vibration environments.

Leak Impact Analysis: According to fluid power industry studies, a single 1/8-inch hydraulic leak can waste over 400 gallons of hydraulic fluid per year. Beyond the cost of replacement fluid (which can exceed $15 per gallon for premium hydraulic oils), there are environmental cleanup costs, potential regulatory fines, and the risk of catastrophic system failure.

Real-World Leak Prevention Comparison

In practical applications, the leak prevention capabilities of NPT and NPSM threads show distinct differences:

| Scenario | NPT Performance | NPSM Performance |

|---|---|---|

| Initial Installation | Excellent when properly installed with appropriate sealant | Very good with proper O-ring or gasket |

| After Thermal Cycling | Generally maintains seal integrity | May require periodic inspection of sealing elements |

| High-Pressure Spikes | Excellent resistance if properly installed | Moderate; depends on sealing element quality |

| Long-Term Durability | Very good; thread sealant may require occasional renewal | Dependent on sealing element condition; may need replacement |

| After Multiple Assembly/Disassembly | Degraded performance; threads may wear | Better maintained; requires new sealing element |

Sealing Methods for NPT vs NPSM Connections

The approach to creating leak-free connections differs significantly between NPT and NPSM threads. Understanding these differences is crucial for proper installation and maintenance.

NPT Sealing Techniques

NPT threads primarily rely on thread deformation for sealing, but additional sealing methods are typically employed:

-

PTFE Tape (Teflon Tape):

- Apply 3-4 wraps in the direction of thread rotation

- Avoid covering the first thread to prevent tape fragments from entering the system

- Best for lower pressure applications (under 3,000 PSI)

-

Liquid Thread Sealants:

- Provide better gap-filling capabilities than tape

- Many formulations contain PTFE particles for enhanced sealing

- Better for higher pressure applications

- Anaerobic sealants harden in the absence of air when compressed between the threads

-

Combination Methods:

- For critical applications, some technicians use both tape and liquid sealant

- Apply thin tape layer first, followed by thread sealant

Expert Tip: For hydraulic systems operating at pressures exceeding 3,000 PSI, liquid thread sealants specifically formulated for high-pressure hydraulics generally outperform PTFE tape in preventing leaks with NPT connections.

NPSM Sealing Techniques

NPSM threads require entirely different sealing approaches:

-

O-Ring Seals:

- Most common sealing method for NPSM threads

- Material selection is critical—NBR (Buna-N) for petroleum-based fluids, EPDM for water-based fluids, Viton for high-temperature applications

- Proper O-ring sizing is essential for effective sealing

-

Bonded Seals/Dowty Washers:

- Metal washer with bonded elastomer inner ring

- Provides excellent vibration resistance

- Higher pressure rating than standard O-rings

-

Metal-to-Metal Seals:

- Used in specialized high-pressure applications

- Requires precision machining of mating surfaces

- May incorporate a soft metal (copper) washer for enhanced sealing

Comparative Sealing Effectiveness

When properly installed, both NPT and NPSM connections can provide leak-free operation, but their long-term performance differs:

| Factor | NPT with Sealant | NPSM with O-Ring |

|---|---|---|

| Initial Leak Prevention | Excellent | Excellent |

| Chemical Compatibility Range | Limited by sealant material | Wide range of elastomers available |

| Temperature Range | -65°F to +400°F (depends on sealant) | -65°F to +600°F (depends on elastomer) |

| Pressure Capability | Up to 10,000+ PSI | Typically up to 6,000 PSI |

| Vibration Resistance | Very good | Good (may require thread locking) |

| Service Life | Extended | Limited by elastomer degradation |

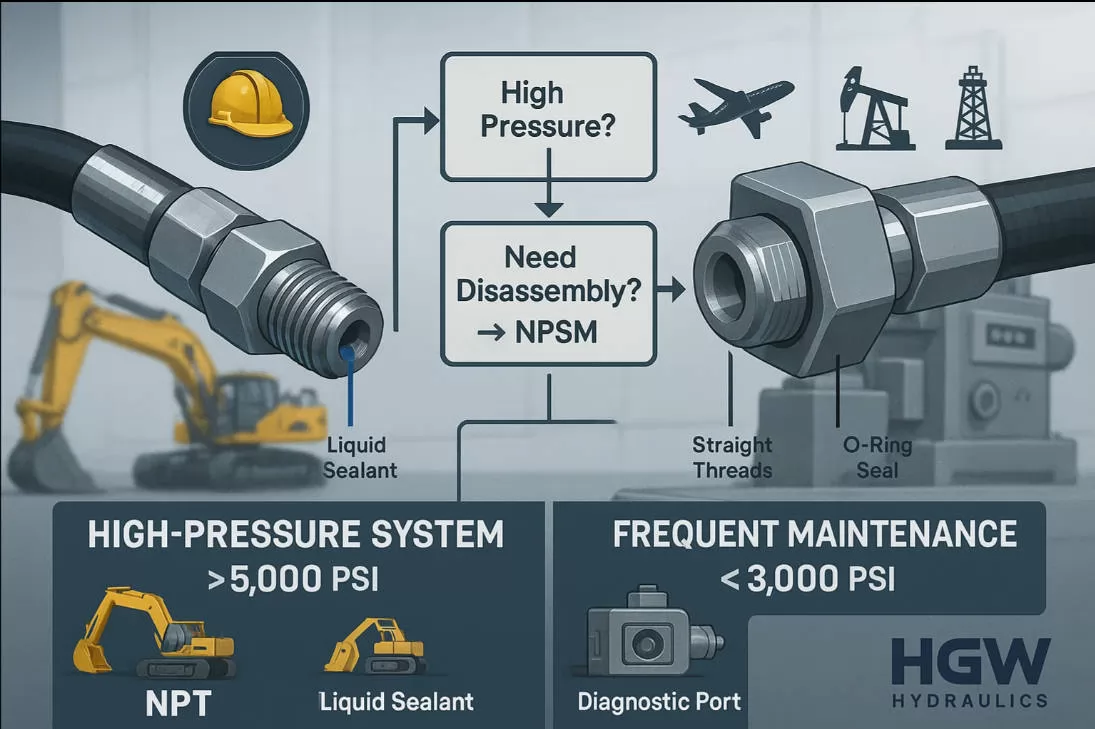

Application Guide: When to Use NPT vs NPSM

Selecting the appropriate thread type depends on several factors including system requirements, operating conditions, and maintenance considerations. Here's a comprehensive guide to help you choose between NPT and NPSM for different hydraulic applications:

When to Choose NPT Threads

NPT connections are generally preferred in these scenarios:

- High-Pressure Systems: For applications operating above 5,000 PSI, NPT threads with appropriate thread sealant often provide superior leak resistance.

- Permanent or Semi-Permanent Installations: When connections are rarely disassembled for maintenance.

- Space-Constrained Applications: NPT fittings often require less space for sealing components.

- Wide Temperature Fluctuations: The metal-to-metal sealing of NPT withstands thermal cycling better than many elastomer seals.

- Legacy System Compatibility: Many existing North American hydraulic systems use NPT threads.

When to Choose NPSM Threads

NPSM connections offer advantages in these circumstances:

- Frequent Disassembly Requirements: Systems requiring regular maintenance or reconfiguration.

- Precision Alignment Needs: When components must maintain precise orientation after tightening.

- Lower-Pressure Applications: Generally suitable for systems operating below 3,000 PSI.

- Corrosive Environments: When using specialized O-ring materials that resist specific chemicals.

- OEM Equipment: Many manufacturers prefer NPSM for simplified assembly processes.

Application Example: In mobile hydraulic equipment such as excavators or loaders, NPT fittings are often used for main pressure lines and permanent connections, while NPSM fittings might be used for diagnostic ports or components requiring frequent service.

Industry-Specific Preferences

Thread selection often follows industry patterns:

| Industry | Common Thread Preference | Rationale |

|---|---|---|

| Construction Equipment | NPT | Durability in harsh environments, vibration resistance |

| Agriculture | NPT | Cost-effectiveness, availability in rural areas |

| Aerospace | NPSM/AN | Precision assembly, weight considerations |

| Marine Hydraulics | NPT | Corrosion resistance with appropriate sealants |

| Industrial Automation | Mixed (NPT for fixed lines, NPSM for components) | Balance of reliability and serviceability |

| Oil & Gas | NPT (often with specialized sealants) | Extreme pressure and temperature requirements |

Your specific application may have unique requirements that override these general guidelines. Consulting with hydraulic specialists at HGW Hydraulic can help determine the optimal thread type for your system's specific needs.

Installation Best Practices for Leak-Free Connections

Proper installation technique is just as important as selecting the right thread type. Follow these best practices to ensure leak-free hydraulic connections:

NPT Installation Guidelines

-

Thread Preparation:

- Clean threads thoroughly with a degreasing solvent

- Inspect for damage, burrs, or cross-threading

- Verify thread compatibility (NPT to NPT)

-

Sealant Application:

- For PTFE tape: Apply 3-4 wraps in clockwise direction (viewed from male thread end)

- For liquid sealant: Apply moderate amount to male threads, focusing on trailing thread flanks

- Avoid excessive sealant that could contaminate the hydraulic system

-

Assembly Technique:

- Hand-tighten until snug

- Use properly sized wrenches (avoid adjustable wrenches when possible)

- Tighten to appropriate torque specification or 1.5-3 turns past hand-tight

- Use a calibrated torque wrench for critical applications

Critical NPT Installation Data: Research shows that 63% of NPT connection failures result from either insufficient or excessive tightening. Following proper torque specifications is essential for leak prevention.

| NPT Size | Recommended Turns Past Hand-Tight | Approximate Torque Range (ft-lbs) |

|---|---|---|

| 1/8" NPT | 2-3 turns | 12-15 ft-lbs |

| 1/4" NPT | 2-3 turns | 25-28 ft-lbs |

| 3/8" NPT | 2-3 turns | 40-43 ft-lbs |

| 1/2" NPT | 2-3 turns | 55-58 ft-lbs |

| 3/4" NPT | 2-3 turns | 85-90 ft-lbs |

| 1" NPT | 1.5-2.5 turns | 110-120 ft-lbs |

NPSM Installation Guidelines

-

O-Ring/Seal Preparation:

- Inspect sealing element for cuts, nicks, or deformation

- Verify correct size and material compatibility with hydraulic fluid

- Lightly lubricate O-ring with system fluid or compatible lubricant

-

Thread Alignment:

- Ensure threads are properly aligned before engagement

- Start threading by hand to prevent cross-threading

- Verify that the sealing element remains properly seated during assembly

-

Tightening Process:

- Tighten to specified torque using calibrated torque wrench

- For face-sealing NPSM, tighten until metal faces contact plus 1/6 to 1/4 turn

- For radial-sealing NPSM, follow manufacturer's specific guidance

Verification and Testing

After installation, proper verification helps ensure leak-free operation:

- Visual Inspection: Check for proper alignment and evidence of crushed or extruded sealing elements.

- Low-Pressure Testing: Initially pressurize system to 10% of operating pressure and check for leaks.

- Incremental Pressure Testing: Gradually increase pressure to operating levels, inspecting connections at each increment.

- Thermal Cycling: For critical systems, perform hot-to-cold cycling to verify seal integrity under temperature changes.

Safety Note: Always follow appropriate safety protocols when pressure testing hydraulic systems. Never use your hands to check for leaks in pressurized systems—hydraulic fluid injection injuries can cause serious tissue damage and may require surgical intervention.

Troubleshooting Common Leakage Issues

Even with careful selection and installation, hydraulic connections may occasionally develop leaks. Understanding how to diagnose and resolve these issues can minimize downtime and prevent system damage.

Common NPT Leakage Problems and Solutions

| Problem | Possible Causes | Solutions |

|---|---|---|

| Immediate Leakage |

|

|

| Delayed Leakage (after pressure/temperature cycles) |

|

|

| Thread Distortion |

|

|

Common NPSM Leakage Problems and Solutions

| Problem | Possible Causes | Solutions |

|---|---|---|

| O-Ring Extrusion |

|

|

| Chemical Degradation |

|

|

| Spiral Failure |

|

|

Diagnostic Tip: When troubleshooting hydraulic leaks, always start with a systematic approach: visual inspection, followed by tightness verification, then low-pressure testing with leak detection fluid. Remember that leaks can travel along components before becoming visible, so the apparent leak location may not be the actual source.

Advanced Diagnostic Methods

For challenging leak detection scenarios, consider these specialized techniques:

- Ultrasonic Leak Detection: Detects the high-frequency sound produced by fluid escaping under pressure, even when the leak is too small to be visible.

- Pressure Decay Testing: Isolating a section of the system and monitoring for pressure drops over time can identify slow leaks.

- Fluorescent Dye Testing: Adding UV reactive dye to the hydraulic fluid makes leaks visible under ultraviolet light.

- Thermal Imaging: For system components at steady state operation, thermal cameras can detect temperature differentials that indicate leaking fluid.

Industry Standards and Compliance Considerations

Understanding the applicable standards and compliance requirements for hydraulic threading is essential for proper system design and maintenance, especially in regulated industries or international markets.

Key Standards Governing NPT and NPSM Threads

- ANSI/ASME B1.20.1: The primary standard defining NPT and NPSM thread dimensions, tolerances, and gauging.

- SAE J514: Specifies standards for hydraulic tube fittings, including thread specifications.

- ISO 7-1: International standard for pipe threads where pressure-tight joints are made on the threads (comparable to NPT).

- ISO 228-1: International standard for pipe threads where pressure-tight joints are not made on the threads (comparable to NPSM).

International Equivalents and Compatibility

When designing hydraulic systems for international use or incorporating imported components, understanding thread compatibility is crucial:

| Region/Standard | NPT Equivalent | NPSM Equivalent | Compatibility Notes |

|---|---|---|---|

| Europe | BSPT (British Standard Pipe Taper) | BSPP (British Standard Pipe Parallel) | Not directly interchangeable; adapters required |

| Japan | PT (JIS B 0203) | G (JIS B 0202) | Similar to BSPT/BSPP; limited interchangeability |

| International (ISO) | Rc (ISO 7-1) | G (ISO 228-1) | ISO 7-1 and NPT are similar but not identical |

| Metric | N/A | Metric Thread (various standards) | No direct equivalent; requires specific adapters |

Compliance Warning: In critical applications, such as aerospace, marine, or oil and gas industries, using non-compliant or incorrectly matched thread types may violate regulatory requirements and could void equipment warranties or insurance coverage. Always verify compliance with relevant industry standards.

Industry-Specific Regulations

Different industries have specialized requirements for hydraulic connections:

- Aerospace (AS, NAS standards): Often requires specific thread types and sealing methods with stringent quality control and traceability.

- Oil and Gas (API standards): Has specialized thread forms designed for extreme pressures and harsh environments.

- Mobile Equipment (SAE standards): Focuses on vibration resistance and serviceability in field conditions.

- Food Processing (3-A, FDA standards): Requires specific materials and thread designs that prevent bacterial harborage.

- Marine (ABS, Lloyd's Register): Emphasizes corrosion resistance and reliability in saltwater environments.

Documentation and Traceability

For quality control and compliance purposes, proper documentation of thread types and installation methods is increasingly important:

- Maintain records of fitting specifications and material certifications

- Document installation torque values and methods

- Create system diagrams indicating thread types at each connection point

- Implement verification processes for critical connections

- Establish regular inspection and maintenance protocols

At HGW Hydraulic, we maintain comprehensive documentation on all fitting types and can provide material certifications and compliance information for regulatory purposes.

Conclusion: Making the Right Thread Choice

Selecting between NPT and NPSM threads is a critical decision that impacts the safety, reliability, and efficiency of hydraulic systems. While both thread types have valid applications, their fundamental differences make them suitable for different scenarios.

Key Takeaways

- NPT threads provide excellent sealing through tapered design and are ideal for high-pressure, permanent installations where leak prevention is paramount.

- NPSM threads offer consistent engagement, better reusability, and precision alignment capabilities, making them suitable for components requiring frequent maintenance or specific orientation.

- Mixing thread types is a common cause of persistent leaks and should be avoided.

- Proper installation technique is just as important as choosing the right thread type.

- Industry-specific standards may dictate thread selection in regulated applications.

Decision Matrix for Thread Selection

When deciding between NPT and NPSM threads, consider these factors:

| If Your Priority Is: | Consider Using: |

|---|---|

| Maximum leak prevention in high-pressure systems | NPT with appropriate liquid thread sealant |

| Frequent disassembly for maintenance | NPSM with quality O-rings |

| Vibration resistance | NPT with anaerobic thread sealant |

| Precise component alignment | NPSM with orientation-specific installation |

| Wide temperature fluctuations | NPT with high-temperature thread sealant |

| Chemical compatibility concerns | NPSM with application-specific elastomers |

| Cost-effectiveness | NPT (generally lower overall cost) |

Expert Recommendation: For critical hydraulic systems where failure could result in safety hazards, environmental damage, or significant downtime, we recommend consulting with hydraulic specialists to determine the optimal threading solution for your specific application.

Future Trends in Hydraulic Threading

The hydraulic industry continues to evolve, with several emerging trends in connection technology:

- Integrated Sealing Systems: Combined thread and seal designs that merge the advantages of both NPT and NPSM.

- Advanced Materials: High-performance polymers and composite materials that enhance sealing capabilities.

- Smart Fittings: Connections with embedded sensors to monitor pressure integrity and predict potential leaks.

- Standardization Efforts: Industry initiatives to harmonize global threading standards for improved interoperability.

At HGW Hydraulic, we stay at the forefront of these developments to provide our customers with the most effective leak prevention solutions for their hydraulic systems.

Need Expert Advice on Hydraulic Threading?

Our team of hydraulic specialists at HGW Hydraulic can help you select the optimal thread type for your specific application, ensuring leak-free performance and system reliability.

Visit www.hgwhydraulics.com or contact our technical support team for personalized assistance.

-

2025 Shanghai Bauma Exhibition China International Construction Machinery ExhibitionUpdate on 2024-12-25

-

2025 Las Vegas International Mining ExhibitionUpdate on 2024-12-25

-

Leading the High-End and Empowering the World | Bauma China 2025, Hgw Successfully ConcludedUpdate on 2024-12-25

-

Hgw's Multi-field Hydraulic Products Appeared at the Exhibition丨MINEXPOUpdate on 2024-12-25

-

2025 PTC ASIAUpdate on 2025-02-12

-

Top 10 Leading Hydraulic Fitting Companies in the World[2025 Updated]Update on 2025-02-27

-

Top 10 Global Suppliers of Hydraulic Hose FittingsUpdate on 2025-03-04

-

HGW's O-Ring Face Seal Fittings(ORFS): From Core to Best UseUpdate on 2025-03-08