BSPP vs BSPT Thread: Key Differences and Applications

Table of Contents

- Introduction to British Standard Pipe Threads

- What is BSPP (British Standard Pipe Parallel)?

- What is BSPT (British Standard Pipe Taper)?

- Key Differences Between BSPP and BSPT

- How to Identify BSPP and BSPT Threads

- Applications in Hydraulic Systems

- Compatibility and Interchangeability Issues

- Selection Guide for Hydraulic Applications

- Installation Best Practices

- Common Issues and Troubleshooting

- Conclusion

Introduction to British Standard Pipe Threads

In the hydraulic industry, proper connection and sealing between components are crucial for system efficiency, safety, and longevity. British Standard Pipe (BSP) thread is one of the most widely used thread standards in hydraulic systems globally, especially in Europe, Asia, and Commonwealth countries. Understanding the differences between the two main types of BSP threads—BSPP (Parallel) and BSPT (Tapered)—is essential for hydraulic system designers, maintenance professionals, and anyone working with fluid power systems.

BSP threads were originally developed in the United Kingdom in the 1940s and have since become an international standard due to their reliability and versatility. When designing hydraulic systems, selecting the correct thread type is critical as it directly impacts the system's pressure handling capability, leak prevention, and overall performance.

Industry Insight: According to hydraulic engineering standards, improper thread matching is responsible for approximately 25% of hydraulic system failures, highlighting the importance of understanding thread differences in professional applications.

What is BSPP (British Standard Pipe Parallel)?

_1747814939_WNo_1088d728.webp)

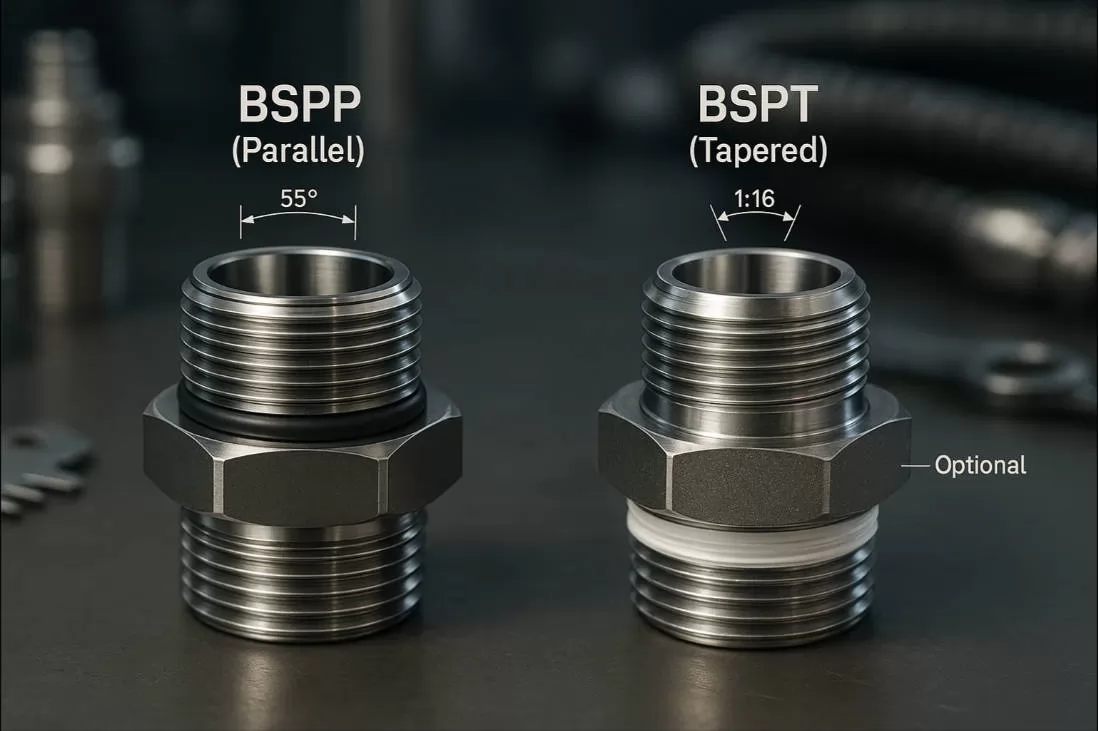

BSPP, also known as G thread (per ISO 228), features cylindrical threads with a constant diameter throughout. This parallel threading system is designed to create mechanical joints that require additional sealing elements to achieve leak-proof connections.

BSPP Characteristics:

BSPP threads maintain a constant diameter from start to finish, giving them their "parallel" designation. The thread angle is 55 degrees, and the threads are measured in inches despite being used in metric systems. What makes BSPP unique in hydraulic applications is its sealing mechanism—it doesn't seal on the threads themselves but relies on a separate sealing element like an O-ring, bonded seal, or metal-to-metal contact faces.

Common BSPP sizes in hydraulic applications range from 1/8" to 2", with the most frequently used sizes in industrial hydraulic systems being 1/4", 3/8", 1/2", and 3/4". Each size corresponds to a specific thread pitch and outside diameter that must be precisely matched for proper fitting assembly.

BSPP Thread Designation:

The BSPP thread is designated by the letter "G" followed by the nominal size. For example, G 1/2 represents a 1/2 inch BSPP thread. In hydraulic documentation, you might also see it referred to as BSPP 1/2" or BSP(F) 1/2" where "F" stands for "flat" or "form," indicating the parallel nature of the thread.

What is BSPT (British Standard Pipe Taper)?

_1747814955_WNo_1098d731.webp)

BSPT, also known as R thread (per ISO 7), features a conical thread form where the diameter decreases along the length of the thread. This design creates a wedge effect when assembled, providing both mechanical connection and sealing capability.

BSPT Characteristics:

The defining feature of BSPT threads is their 1:16 taper ratio, meaning the diameter decreases by 1 unit for every 16 units of length. Like BSPP, BSPT threads have a 55-degree thread angle. However, unlike BSPP, BSPT threads create a seal through the wedging action of the threads themselves, with thread deformation occurring during installation to create metal-to-metal sealing.

In hydraulic systems, BSPT connections are particularly valued for their self-sealing capability in high-pressure applications, though they typically require thread sealant for optimal performance. The tapered design provides progressive tightening, making it easier to achieve the correct torque during installation.

BSPT Thread Designation:

BSPT threads are designated by the letter "R" followed by the nominal size. For example, R 1/2 represents a 1/2 inch BSPT thread. In technical documentation, you might also see it referred to as BSPT 1/2" or BSP(T) 1/2" where "T" explicitly indicates the tapered nature of the thread.

Key Differences Between BSPP and BSPT

| Feature | BSPP (G Thread) | BSPT (R Thread) |

|---|---|---|

| Thread Profile | Parallel/Cylindrical | Tapered/Conical (1:16 ratio) |

| Sealing Mechanism | Requires separate sealing element (O-ring, bonded washer) | Self-sealing via thread wedging action (with sealant) |

| Thread Angle | 55 degrees | 55 degrees |

| ISO Standard | ISO 228 | ISO 7 |

| Connection Type | Mechanical joint with separate seal | Interference fit joint |

| Typical Applications | Low to medium pressure hydraulic systems, precision applications | High-pressure applications, temporary connections |

| Reusability | Highly reusable | Limited reusability (threads deform slightly during installation) |

The fundamental difference lies in how these threads create a seal. BSPP relies on separate sealing components making it ideal for hydraulic systems requiring frequent disassembly, while BSPT creates interference-based seals making it suitable for permanent or semi-permanent high-pressure connections.

Engineering Note: In hydraulic applications, BSPP connections generally offer better vibration resistance due to their more consistent thread engagement, while BSPT connections often provide superior pressure containment in static applications.

How to Identify BSPP and BSPT Threads

Correctly identifying thread types is crucial when servicing or designing hydraulic systems. Mismatched threads can lead to leakage, connection failure, and potential safety hazards.

Visual Inspection:

The most immediate way to distinguish between BSPP and BSPT is through visual inspection:

- BSPP: Threads appear uniform from start to finish with consistent diameter

- BSPT: Visible taper with diameter decreasing from one end to the other

Thread Gauge Testing:

For more precise identification, hydraulic technicians use thread gauges specifically designed for BSP threads. These gauges have teeth that match the thread profile and angle, allowing for positive identification of both thread type and size.

Marking Systems:

In professional hydraulic fittings, thread types are typically marked according to ISO standards:

- G 1/2 indicates a 1/2 inch BSPP thread

- R 1/2 indicates a 1/2 inch BSPT thread

- Rc 1/2 indicates an internal (female) BSPT thread

For hydraulic components without clear markings, professional thread identification kits that include both BSPP and BSPT gauges are essential for accurate identification.

Applications in Hydraulic Systems

Understanding the ideal applications for each thread type is essential for optimal hydraulic system design and performance.

BSPP Applications:

BSPP threads excel in applications requiring:

- Frequent disassembly and maintenance: Their parallel design allows for multiple assembly/disassembly cycles without thread degradation, making them ideal for hydraulic components requiring regular service.

- Precision alignment: In hydraulic manifold blocks and precision components where exact positioning is critical.

- Connection with separate sealing elements: Systems designed around bonded seals, O-rings, or flat gasket sealing methods.

- Mobile hydraulic equipment: Where vibration resistance is important and components may need frequent servicing.

In the hydraulic industry, BSPP connections are commonly found in test points, instrumentation connections, and multi-port hydraulic manifolds where precise alignment and frequent access are required.

BSPT Applications:

BSPT threads are preferred for:

- High-pressure systems: The wedging action provides excellent pressure containment, particularly in static applications.

- Space-constrained installations: Where separate sealing elements would be difficult to accommodate.

- Semi-permanent connections: Components intended to remain assembled for extended periods.

- Applications using thread sealant compounds: The taper design works well with anaerobic and PTFE-based sealants.

In hydraulic systems, BSPT connections are often used for drain lines, tank connections, and auxiliary circuits where maximum pressure containment is needed and frequent disassembly is not anticipated.

Compatibility and Interchangeability Issues

One of the most challenging aspects of BSP threads in hydraulic systems is understanding their compatibility limitations.

BSPP to BSPP Connections:

These connections work well with appropriate sealing elements. The parallel threads align precisely, and with the correct O-ring or bonded seal, they provide reliable, leak-free connections in hydraulic applications.

BSPT to BSPT Connections:

When connecting male and female BSPT threads, proper thread engagement is crucial. For hydraulic applications, industrial standards typically recommend 3-5 threads of engagement for optimal sealing and mechanical strength.

BSPP to BSPT Connections:

This combination presents significant challenges in hydraulic systems:

- Male BSPP to female BSPT: This connection can achieve partial thread engagement but will not create a reliable seal for hydraulic pressures. The parallel male thread cannot conform to the tapered female thread.

- Male BSPT to female BSPP: While this connection may initially seem tight, the tapered male thread will only engage properly at the beginning of the parallel female thread, leading to reduced mechanical strength and potential failure under hydraulic pressures.

Safety Warning: Mixing BSPP and BSPT threads in hydraulic systems can create dangerous conditions, including sudden fitting failure under pressure. Always match thread types for safety-critical hydraulic applications.

Adapter Solutions:

In hydraulic systems where different thread types must be integrated, purpose-designed adapters should be used rather than attempting direct connection between incompatible threads. These adapters typically feature the appropriate thread type on each end with proper internal engineering to maintain flow characteristics and pressure capability.

Selection Guide for Hydraulic Applications

When designing or maintaining hydraulic systems, thread selection should be based on specific application requirements:

Choose BSPP when:

- The hydraulic connection requires frequent maintenance access

- Precise component alignment is necessary

- The system experiences significant vibration

- Connection standardization is important (BSPP is more widely used in modern hydraulic systems)

- Working with metric hydraulic components (BSPP is more common in metric system designs)

Choose BSPT when:

- Maximum pressure containment is the priority

- Space constraints limit the use of separate sealing elements

- The connection is intended to be semi-permanent

- Working with older hydraulic equipment (particularly equipment of British origin)

- Connecting to pipe threads in mixed pneumatic/hydraulic systems

For critical hydraulic applications, system pressure ratings, temperature fluctuations, and fluid compatibility should all factor into thread selection decisions.

Installation Best Practices

Proper installation techniques differ significantly between BSPP and BSPT connections in hydraulic systems.

BSPP Installation:

- Ensure threads are clean and undamaged

- Verify the correct sealing element (bonded washer, O-ring) is used

- Position the sealing element properly—typically against a machined face

- Tighten to the manufacturer's recommended torque specification

- Avoid over-tightening, which can damage the sealing element

In hydraulic applications, BSPP connections should be tightened to create controlled compression of the sealing element, not thread deformation. Using a calibrated torque wrench is highly recommended for hydraulic BSPP connections.

BSPT Installation:

- Clean threads thoroughly

- Apply appropriate thread sealant (PTFE tape or liquid sealant formulated for hydraulic applications)

- For PTFE tape, wrap in the direction of thread engagement (typically clockwise for external threads)

- Engage threads carefully to avoid cross-threading

- Tighten until firm resistance is felt, typically 2-3 turns past hand-tight for hydraulic applications

When using PTFE tape on BSPT threads in hydraulic systems, leave the first thread exposed to prevent tape fragments from entering the hydraulic fluid, which could cause contamination and valve issues.

Common Issues and Troubleshooting

Even with proper selection, hydraulic connections using BSP threads can sometimes develop problems.

Leakage Issues:

- BSPP Leaks: Typically result from damaged sealing elements, insufficient tightening, or misalignment. Inspect the sealing element for cuts or deformation and check that connection faces are properly aligned and free from damage.

- BSPT Leaks: Often caused by insufficient thread sealant, improper sealant application, or over/under-tightening. Re-wrap with PTFE tape or apply fresh liquid sealant following proper application procedures.

Thread Damage:

- Galled Threads: Result from metal-to-metal contact without proper lubrication or from cross-threading. In hydraulic systems, this can lead to particulate contamination. Replace damaged fittings rather than attempting repair.

- Stripped Threads: Typically caused by over-tightening or mismatched thread types. Replacement of the component is usually necessary in hydraulic applications where pressure integrity is critical.

Assembly Problems:

- Difficult Assembly: If threads don't engage smoothly, stop immediately to prevent damage. Verify thread types match and check for debris or damage.

- Bottoming Out: When a fitting tightens but still leaks, it may be "bottoming out" before the sealing surfaces engage. Use appropriate thread length or add a washer to adjust depth.

Maintenance Tip: Keep a thread identification kit in your hydraulic maintenance toolkit. Being able to positively identify BSPP and BSPT threads can prevent costly connection mistakes and system downtime.

Conclusion

Understanding the differences between BSPP and BSPT threads is essential for anyone working with hydraulic systems. While both thread types serve important roles in fluid power applications, their distinct characteristics make them suitable for different scenarios.

BSPP threads offer excellent reusability, precise alignment, and reliable sealing with appropriate sealing elements, making them ideal for hydraulic components requiring frequent maintenance access. BSPT threads provide excellent pressure containment through their self-sealing design, making them suitable for high-pressure, semi-permanent hydraulic connections.

By selecting the appropriate thread type for each application, ensuring proper installation techniques, and avoiding mixed thread connections, hydraulic system designers and maintenance professionals can achieve optimal system performance, longevity, and safety.

At HGW Hydraulic, we understand the critical importance of proper connections in hydraulic systems. Our engineering team is available to assist with thread identification, component selection, and system design to ensure your hydraulic systems operate at peak efficiency with minimal downtime.

For more information about hydraulic fittings, components, and system design, visit HGW Hydraulic or contact our technical support team.

-

2025 Shanghai Bauma Exhibition China International Construction Machinery ExhibitionUpdate on 2024-12-25

-

2025 Las Vegas International Mining ExhibitionUpdate on 2024-12-25

-

Leading the High-End and Empowering the World | Bauma China 2025, Hgw Successfully ConcludedUpdate on 2024-12-25

-

Hgw's Multi-field Hydraulic Products Appeared at the Exhibition丨MINEXPOUpdate on 2024-12-25

-

2025 PTC ASIAUpdate on 2025-02-12

-

Top 10 Leading Hydraulic Fitting Companies in the World[2025 Updated]Update on 2025-02-27

-

Top 10 Global Suppliers of Hydraulic Hose FittingsUpdate on 2025-03-04

-

HGW's O-Ring Face Seal Fittings(ORFS): From Core to Best UseUpdate on 2025-03-08